Product Description

Deli Roll Forming Machine Manufacturer

WHAT IS ROLL FORMING

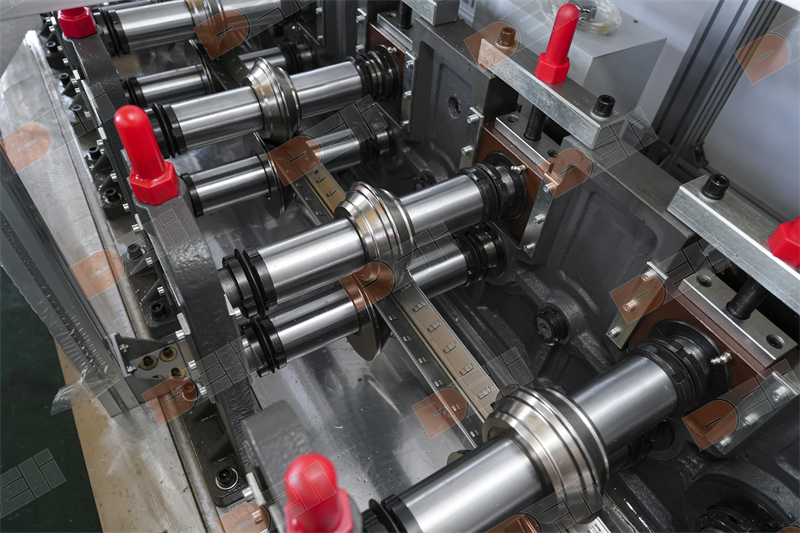

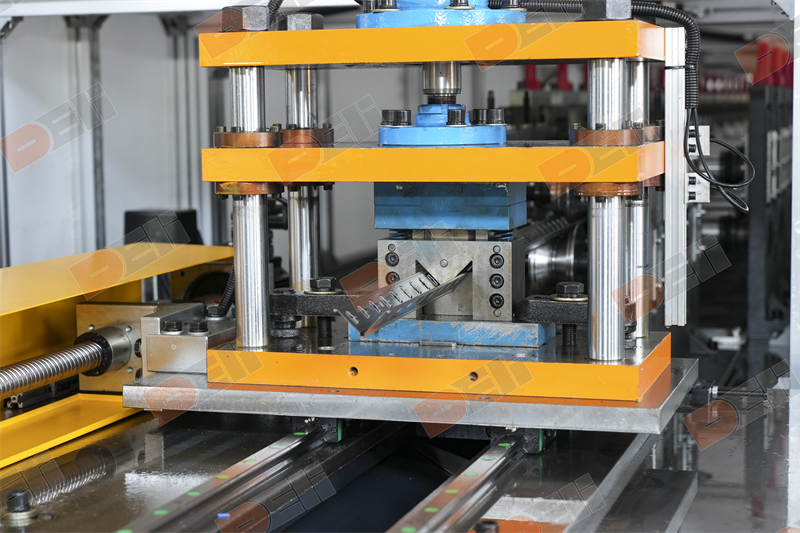

Roll forming is a metalworking process in which a continuous strip of metal is passed through a series of rolls to shape it into a desired profile gradually.

The metal is typically fed through a series of rollers that gradually bend and shape it into the desired form, creating a precise and consistent profile.

The process creates a uniform cross-section by bending the metal or steel sheet along a predetermined path.

Roll forming is commonly used in the manufacturing industry to produce parts and products with consistent and precise shapes

It is a cost-effective method for producing long lengths of consistently shaped metal parts.

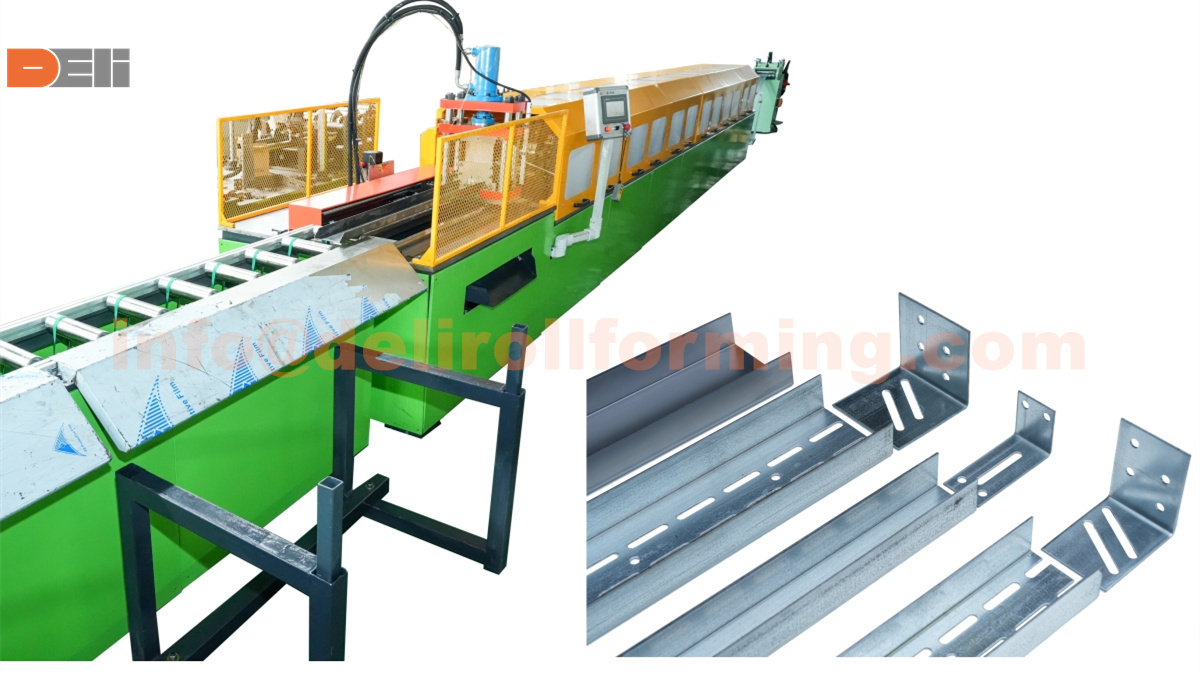

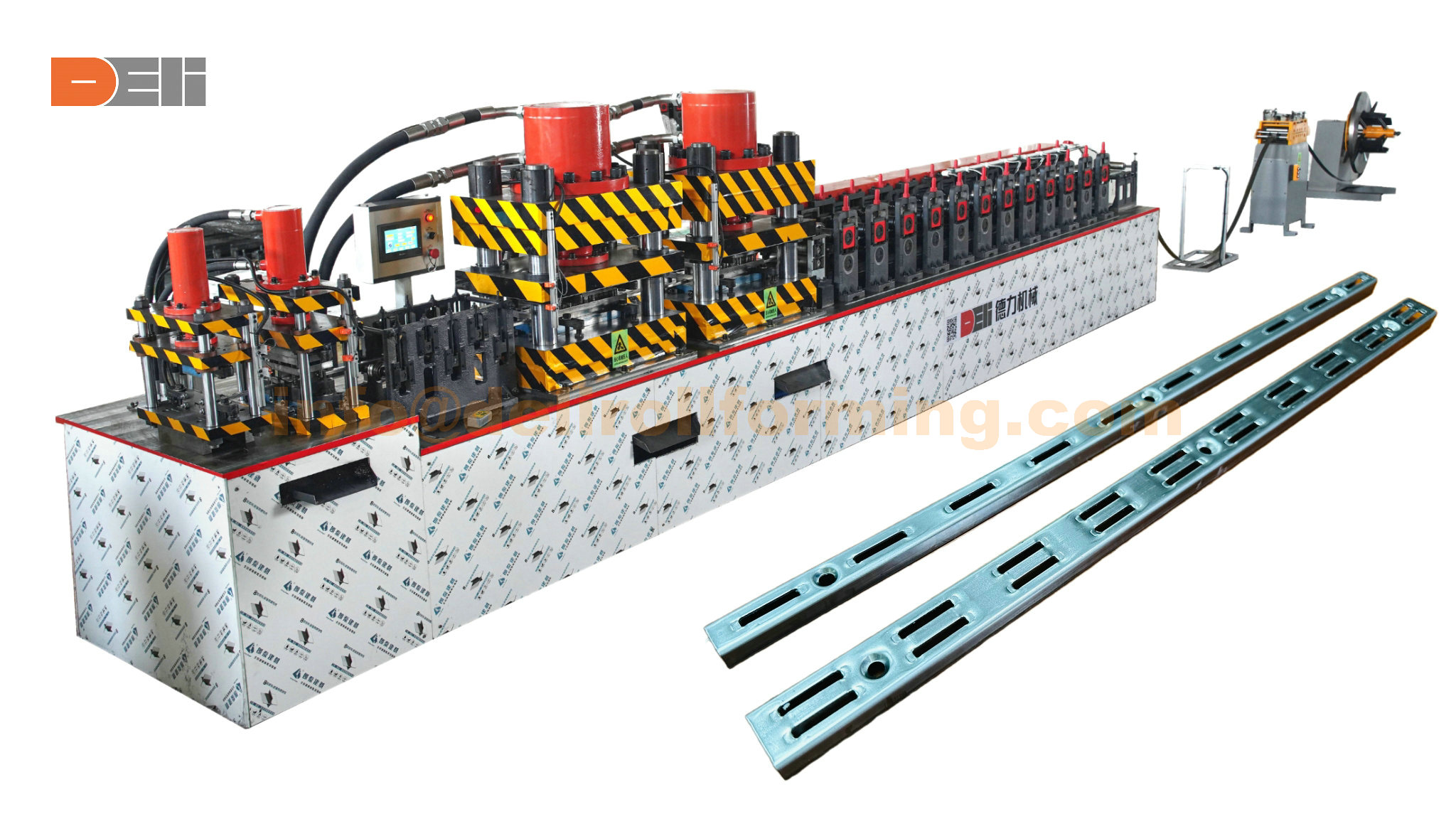

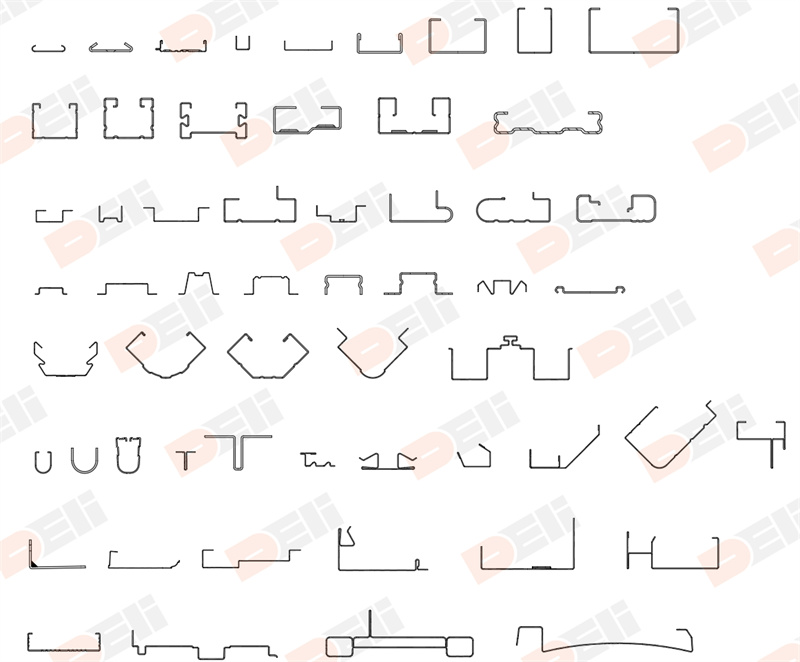

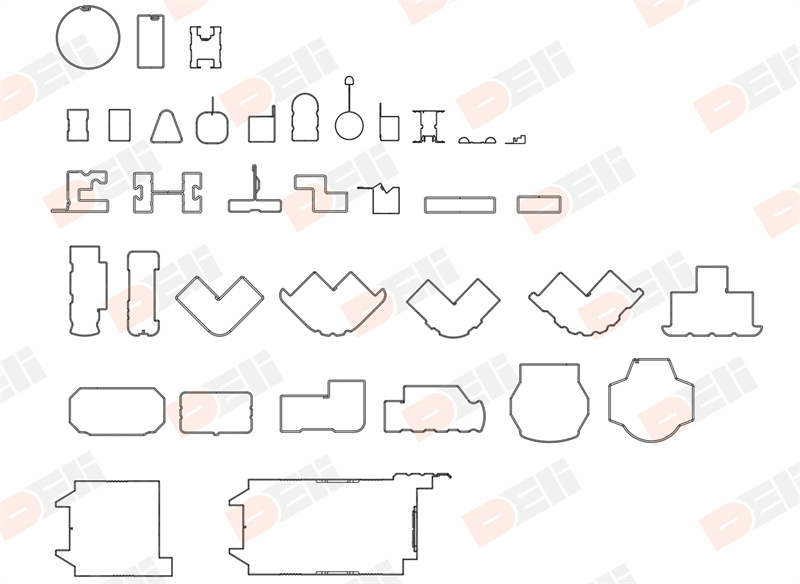

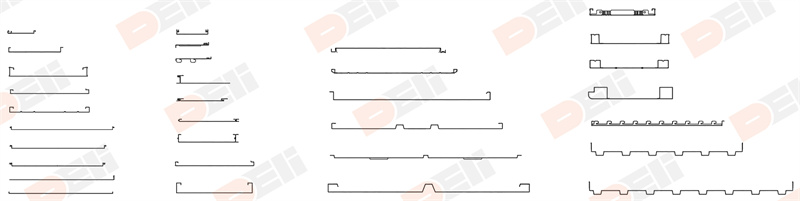

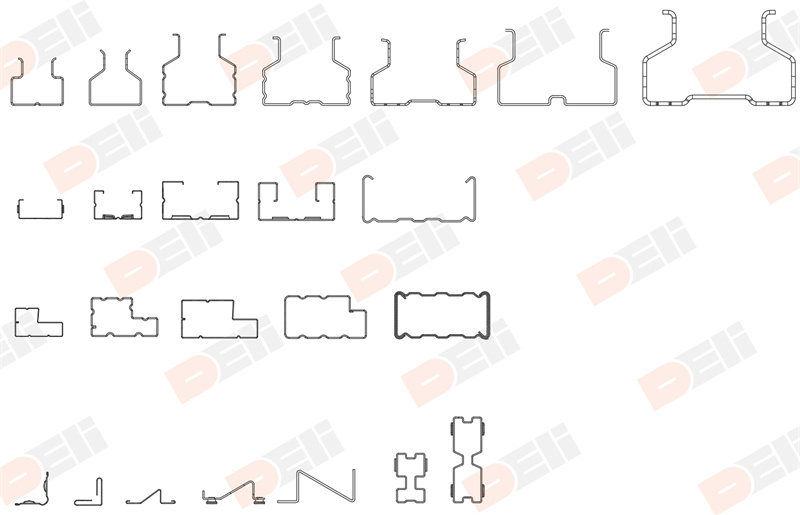

PROFILES

CLOSED PROFILES

PANELS / SHELVES

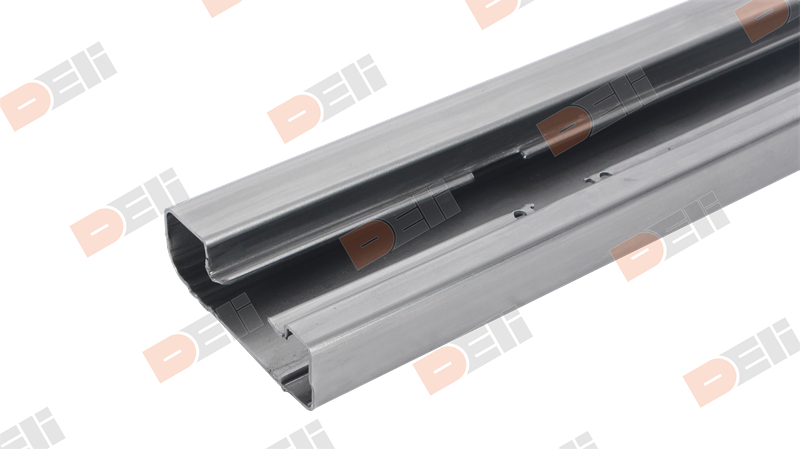

Multiple sizes in one production line:

It can produce panels from 100-1500mm in width, with different heights and lengths

featuring a CNC auto-bending system

Automatic, labor-saving, efficient

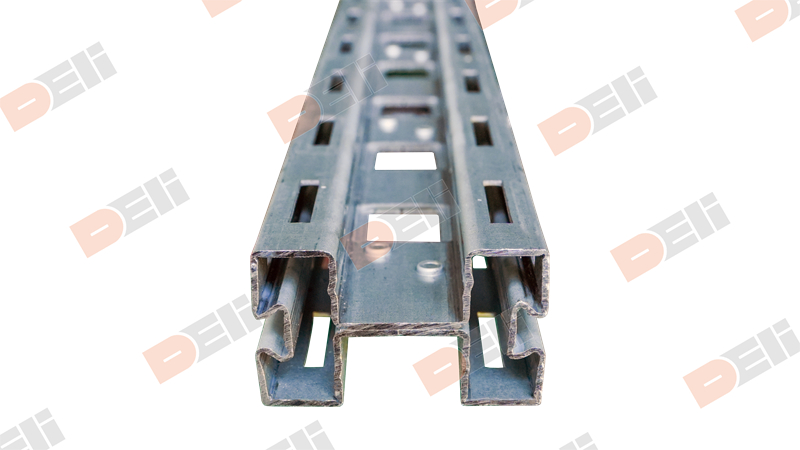

RACKING & SHELVEING SYSTEM

ADVANTAGES OF ROLL FORMING

Cost-effective: Roll forming is a cost-effective manufacturing process, as it allows for high-volume production with minimal waste material.

Consistent quality: Roll forming produces precise and consistent parts with tight tolerances, ensuring high-quality finished products.

Versatility: Roll forming can be used to create a wide range of shapes and sizes, making it a versatile process for various industries and applications.

Speed: Roll forming is a fast and efficient process, capable of producing large quantities of parts in a short amount of time.

Strong and durable: Roll-formed parts are typically stronger and more durable than parts created through other manufacturing processes, making them ideal for applications requiring high strength and endurance.

Complex shapes: Roll forming can produce complex shapes and designs that may be difficult or impossible to achieve through other manufacturing methods.

Flexibility: Roll forming can be easily adapted to produce different shapes and sizes, making it a flexible process for meeting various production requirements.

Reduced labor costs: Roll forming is a highly automated process, reducing the need for manual labor and lowering overall production costs.

HOW DO ROLL FORMING MACHINES MAKE

1. Requirement Analysis: The first step in the roll forming machine design process is to gather all the requirements from the customer.

This includes the type of materials to be used, the desired output, and any specific features or functions that the machine needs to have.

2. Concept Design: Once all the requirements have been established, the design team will come up with several concept designs for the roll forming machine.

This may involve sketching out different ideas, conducting feasibility studies, and determining the best approach to meet the customer’s needs.

3. Detailed Design: Once a concept design has been chosen, the design team will then work on creating a detailed design of the roll forming machine.

This involves creating detailed drawings, specifications, and calculations to ensure that the machine will function as intended.

4. Production: Once the design is finished, the team can move forward with production of the roll forming machine. This may involve sourcing materials, manufacturing components, and assembling the machine according to the detailed design.

5. Installation and Commissioning: The final step in the design process is to install and commission the roll forming machine at the customer’s facility. This involves setting up the machine, calibrating it, and training operators on how to use and maintain it.

Overall, the roll forming machine design process is a comprehensive one that involves understanding the customer’s requirements, designing a machine to meet those requirements, and ensuring that it functions properly through testing and validation.

Deli Roll Forming has been a trusted provider of roll forming services since 2003. With over 20years of experience, our expert team is dedicated to delivering high-quality roll forming products to meet the unique needs of our customers. From design to production, we are committed to providing innovative solutions that exceed expectations. Partner with Deli Roll Forming for all your roll forming needs.